Introduction: The Critical Role of Fieldbus in Industrial Automation

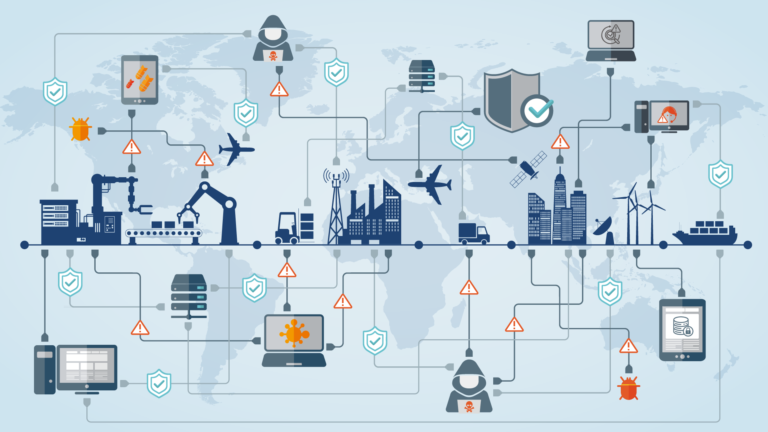

Fieldbus protocols form the backbone of industrial automation, enabling real-time communication between controllers, sensors, and actuators in sectors like manufacturing, energy, automotive, and process control. Standards like PROFINET, EtherCAT, Modbus TCP, and DeviceNet have been widely adopted to ensure low-latency, deterministic communication in mission-critical environments.

However, these protocols were designed in an era where cybersecurity was not a primary concern. The assumption was that isolated operational technology (OT) networks provided sufficient security. With the rise of Industry 4.0, IIoT (Industrial Internet of Things), and cloud-integrated automation, Fieldbus networks are now increasingly exposed to sophisticated cyber threats, particularly Distributed Denial of Service (DDoS) and advanced hacking attacks.

In this article, we delve into the security weaknesses of Fieldbus standards, explore how DDoS and hacking attacks compromise these industrial networks, and propose an AES-256-based encryption solution—one that eliminates the overhead and security risks of traditional key exchange mechanisms.

The Security Weaknesses of Fieldbus Networks

Unlike traditional IT networks, Fieldbus communication protocols were not originally built with encryption, authentication, or intrusion detection mechanisms. Some key security challenges include:

Lack of Built-in Encryption and Authentication

Most Fieldbus protocols rely on unencrypted communication, making them vulnerable to eavesdropping, man-in-the-middle (MITM) attacks, and replay attacks. Attackers can:

-

- Intercept sensitive control signals to manipulate industrial processes.

- Replay previous commands, causing actuators and controllers to operate incorrectly.

- Modify configuration settings, leading to unsafe operating conditions.

Susceptibility to DDoS Attacks

Industrial control networks require low latency and high availability. However, attackers can exploit the lack of traffic filtering mechanisms in Fieldbus networks to launch DDoS attacks by:

-

- Flooding controllers with malformed packets, overloading processing resources.

- Sending continuous “start/stop” commands to disrupt factory automation.

- Triggering network-wide synchronization failures, causing operational downtime.

Weaknesses in Shared Network Topologies

Many Fieldbus implementations rely on shared Ethernet-based infrastructures where multiple devices communicate over the same physical network. This makes them vulnerable to:

-

- Traffic hijacking and spoofing, allowing attackers to impersonate valid devices.

- Packet injection, where malicious actors introduce harmful commands.

- Network scanning, enabling reconnaissance for future attacks.

Key Management Issues in Existing Security Approaches

Some modern Fieldbus implementations attempt to introduce encryption using SSL/TLS or IPSec, but these solutions present two major challenges:

-

- High computational overhead, leading to increased latency and jitter.

- Key exchange vulnerabilities, where attackers can intercept or compromise the Diffie-Hellman or RSA-based key exchange process.

To secure Fieldbus networks effectively, we need an encryption approach that is both lightweight and resistant to key exchange attacks.

Real-World Attacks on Fieldbus and Industrial Networks

TRITON Malware Attack on Safety Instrumented Systems (SIS) – 2017

In 2017, a sophisticated malware attack, TRITON (a.k.a. TRISIS), targeted the Triconex Safety Instrumented System (SIS) used in oil and gas refineries.

-

- The attackers gained remote access to the Safety PLC (Programmable Logic Controller) and injected malicious code into the system.

- The attack attempted to disable fail-safe mechanisms, creating conditions for potential industrial accidents.

- The malware exploited unprotected Fieldbus protocols to move laterally within the network.

Lesson: If the Fieldbus communication had been encrypted with AES-256, attackers would not have been able to manipulate control signals or modify SIS logic.

Stuxnet – The Cyber Weapon That Targeted PLCs – 2010

Stuxnet was one of the most high-profile cyberattacks on industrial control systems. The malware:

-

- Infected Siemens PLCs via Modbus TCP communication, which lacked encryption.

- Intercepted and modified process signals, causing centrifuges at an Iranian nuclear facility to spin out of control and ultimately break.

- Spread through USB drives and infected Windows-based industrial control software.

Lesson: If Modbus TCP had enforced strong AES-256 encryption and authentication, Stuxnet would not have been able to alter PLC logic undetected.

Future Attack Scenario: Ransomware in Smart Manufacturing

As more factories integrate cloud-based automation and AI-driven control systems, ransomware attacks could target Fieldbus networks to shut down production lines.

-

- Attackers could encrypt Fieldbus traffic, holding operational data hostage.

- They could inject malicious shutdown commands, forcing factories to halt production.

- Attackers might hijack safety-critical systems, demanding ransom payments to restore control.

Mitigation: AES-256 encryption with a tamper-proof authentication system ensures that only authorized control commands are processed, preventing such ransomware-based attacks.

Why AES-256 Encryption Without Traditional Key Exchange is the Future

AES-256 (Advanced Encryption Standard with 256-bit keys) is widely regarded as one of the most secure and efficient encryption algorithms for protecting data in transit. However, most implementations rely on a separate key exchange mechanism (such as Diffie-Hellman or RSA key exchange), which introduces security gaps. A better approach is to use a key exchange-free encryption model.

Advantages of AES-256 Without Key Exchange

- Eliminates Man-in-the-Middle (MITM) and Quantum Threats

A pre-shared, dynamically synchronized AES-256 key system ensures that no external key exchange process is needed, eliminating this attack vector entirely.

- Prevents Replay Attacks and DDoS Packet Injection

Time-based or nonce-based key evolution mechanisms prevent attackers from replaying or injecting malicious packets into the Fieldbus network. - Minimal Computational Overhead, Preserving Real-Time Performance

AES-256 encryption can be hardware-accelerated using FPGA-based inline encryptors, reducing processing latency. - Seamless Integration with Existing Fieldbus Protocols

AES-256 encryption can be implemented at the Ethernet or transport layer, allowing Fieldbus protocols to remain unchanged at the application level.

A Practical Implementation: Stealth – The Next-Gen AES-Based Encryption for Fieldbus Security

At Pantherun, we have developed Stealth, an AES-256-based encryption solution optimized for Fieldbus and industrial networking. Unlike traditional encryption methods that rely on computationally expensive key exchanges, Stealth introduces:

-

- A unique patented key synchronization mechanism, eliminating the need for traditional key exchange protocols like Diffie-Hellman.

- Low-latency, hardware-accelerated encryption, ensuring that real-time industrial control loops remain unaffected.

- Tamper-proof authentication, preventing unauthorized devices from participating in the network.

- Automatic mitigation of DDoS packet injection attacks, ensuring uninterrupted factory operations.

By implementing Stealth, Fieldbus networks can achieve military-grade encryption security without compromising latency, compatibility, or network efficiency.

Conclusion: The Urgent Need for Secure Fieldbus Networks

The time to secure Fieldbus networks is now.

About Pantherun:

Pantherun is a cyber security innovator with a patent pending approach to data protection, that transforms security by making encryption possible in real-time, while making breach of security 10X harder compared to existing global solutions, at better performance and price.